![]()

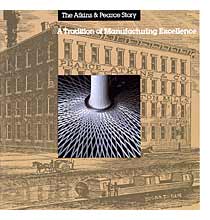

The Atkins & Pearce Manufacturing Company is an industrial braider in

Cincinnati, producing braided sleeving for electrical cords, braided candle

wicking, stator lacing cord for electrical motors, decorative trim for caskets

and bowling bags and metallic braid for decorative packaging. They also package

glass yarn for other braiders.

The

Problem

At the time they approached us about energizing their marketing program in

1985, annual sales had been flat for a decade, at about $10 million. The company

was 200 years old, located in old factory buildings in downtown Cincinnati.

Since there had been no essential change in braiding technology during that

time, the company operated with thousands of braiding machines more than 100

years old. There were many positives about the company, however. Management

was lean and efficient and production was mostly automated, allowing them

to be the low cost producer in each of their markets. Their quality was superior,

and they were well regarded where they were known. They were also cash-rich.

The

Solution

The

Solution

During our first meeting in their offices, we made several suggestions for

improving sales techniques. The next month, even before we returned with a

marketing plan, sales increased by more than 10%.

We soon discovered that virtually all their existing markets were classically

mature, with one in immediate danger of collapsing due to new technology and

one unprofitable due to intense competition and low margins. We identified

threats and opportunities in each market segment and for the corporation and

made several specific recommendations:

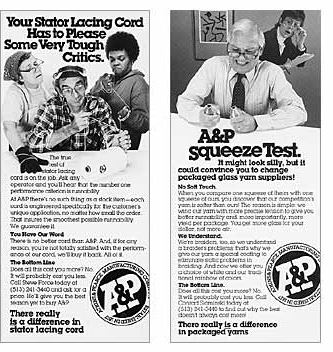

1) In the packaged glass yarn segment, we determined that their opportunities

lay in developing white yarn accounts (as opposed to the primarily colored

yarns which they sold at that point).

2) In the candle wicking segment, threatened by inexpensive Chinese imports,

we recommended they focus on capturing projected growth among current customers

in the domestic market.

3)

In their largest segment, sleeving, we recommended they try to achieve strong

market dominance by encouraging potential customers to eliminate their in-house

capacity. This was done by buying that capacity or producing sleeving at a

lower cost. 4) In the extremely mature stator lacing cord segment, which was threatened

by new technology, we suggested identifying export opportunities and protecting

their domestic position by acquiring capacity in the new technology.

5) In the high-profit decorative trim segments, the company lacked market

information on opportunities. We recommended additional research before deciding

on a marketing direction.

In addition, we concurred with the company's desire to enter the advanced

composites market, where their low-cost production techniques could bring

economy to high-tech processes, and much of our effort over the next five

years was directed toward this end.

In addition, we concurred with the company's desire to enter the advanced

composites market, where their low-cost production techniques could bring

economy to high-tech processes, and much of our effort over the next five

years was directed toward this end.

Other

issues we presented were the need for competitive market data and knowledge

of customers' markets and technologies; the need for a more aggressive selling

posture, including a systematic sales call program; and the need to become

involved in industry supplier networks.

In all segments, awareness of the company was surprisingly low, and we recommended

increasing promotion. In fact, the company had produced only one item, a sample

card of metallic braid, in its entire 200 year history. The subsequent success

of the increased promotion was fueled to a great extent by superior product

quality and the company's low cost of production. A comprehensive marketing

plan was prepared, and, to the credit of the company, implemented. The plan

included specific promotional tools and activities and a line item budget.

Among the promotional items produced:

New corporate identity

Corporate capability brochure

Trade media advertising in selected segments

Trade show booths

Product literature

The Result

After the first year of increased marketing activity, sales had doubled. Sales

doubled again by the fourth year. By the fifth year, Atkins & Pearce had

built and moved into their own industrial park, a much larger facility in

Covington, Kentucky. The company also successfully penetrated the advanced

composites market, where margins were significantly higher than their traditional

mature markets. Their new end products included braided light poles and braided parts for the automotive and aerospace industries, and they were working with engineers at Drexel University to braid an entire car body.